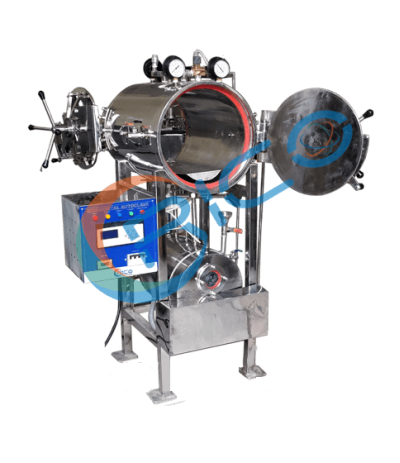

Horizontal autoclaves manufactured by RICO are smart investments for hospitals and laboratories, where large amounts of sterilization are required. Designed by ergonomically, our high class horizontal autoclave sterilizers are ideal for educational facilities, biotech industries, pharmaceutical industries, hospitals, research centers and food and beverage industries. These units strictly meet sterilization requirements and are suitable for sterilizing hospital dressing and surgical instruments, rubber and plastic items, glassware and utensils etc.

We create both rectangular and cylindrical horizontal autoclave systems, which can be further customized to meet the specific requirements of our customers. The scope of optimization includes construction material, internal tank volume, valve and printer options. These units can also be constructed with vacuum drying option; For this purpose, the vacuum (through vacuum pump) provision is implemented in the chamber. Each of our horizontal autoclave units provides highly satisfying performance and competitive price guarantees.

-400x463.jpg)

-400x463.jpg)